Published: 08/2024

Six Sigma is a metrics-driven process improvement methodology that focuses on eliminating defects and reducing variation. In the early 1980’s Motorola developed the Six Sigma Principles. The core proposition of Six Sigma is that variation in manufacturing processes is the main culprit for defects. Eliminating variation will help to eliminate defects, decrease overall cost, and increase customer satisfaction. A key focus of Six Sigma is the use statistical tools to identify and correct the root causes of variation. Six Sigma uses the DMAIC (Define, Measure, Analyze, Improve, Control) roadmap for problem solving and process improvement.1

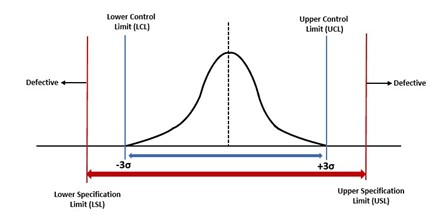

The term Six Sigma refers to six standard deviations from a target value. The mean of the process distribution is six standard deviations away from the lower specification limit, and six standard deviations away from the upper specification limit. This means that the process produces the desired output (defect-free product) 99.99966% of the time: a defect occurs only twice for every one million products. Today, most healthcare processes perform at 3 to 4 standard deviation levels, meaning that errors occur between 6.7 and 2.3% of the time (Figure 1, Table 1).

Figure 1. Six Sigma Lower Specification and Upper Specification limit.

| Sigma Level | Items without Defect (%) |

Defects per million products |

|---|---|---|

| 1.0 | 30.90 | 691,462 |

| 2.0 | 69.10 | 308,538 |

| 3.0 | 93.30 | 66,808 |

| 4.0 | 99.40 | 6,210 |

| 5.0 | 99.98 | 233 |

| 6.0 | 99.99966 | 2 |

References

1Agency for Healthcare Research and Quality. “Ways to Approach the Quality Improvement Process.” https://www.ahrq.gov/cahps/quality–improvement/improvement–guide/4–approach–qiprocess/sect4part2.html. Accessed 21 August 2024.

2Six Sigma Material. “Short Term Sigma Conversion Table.” www.six–sigma–material.com/Tables.html. Accessed 21 August 2024.